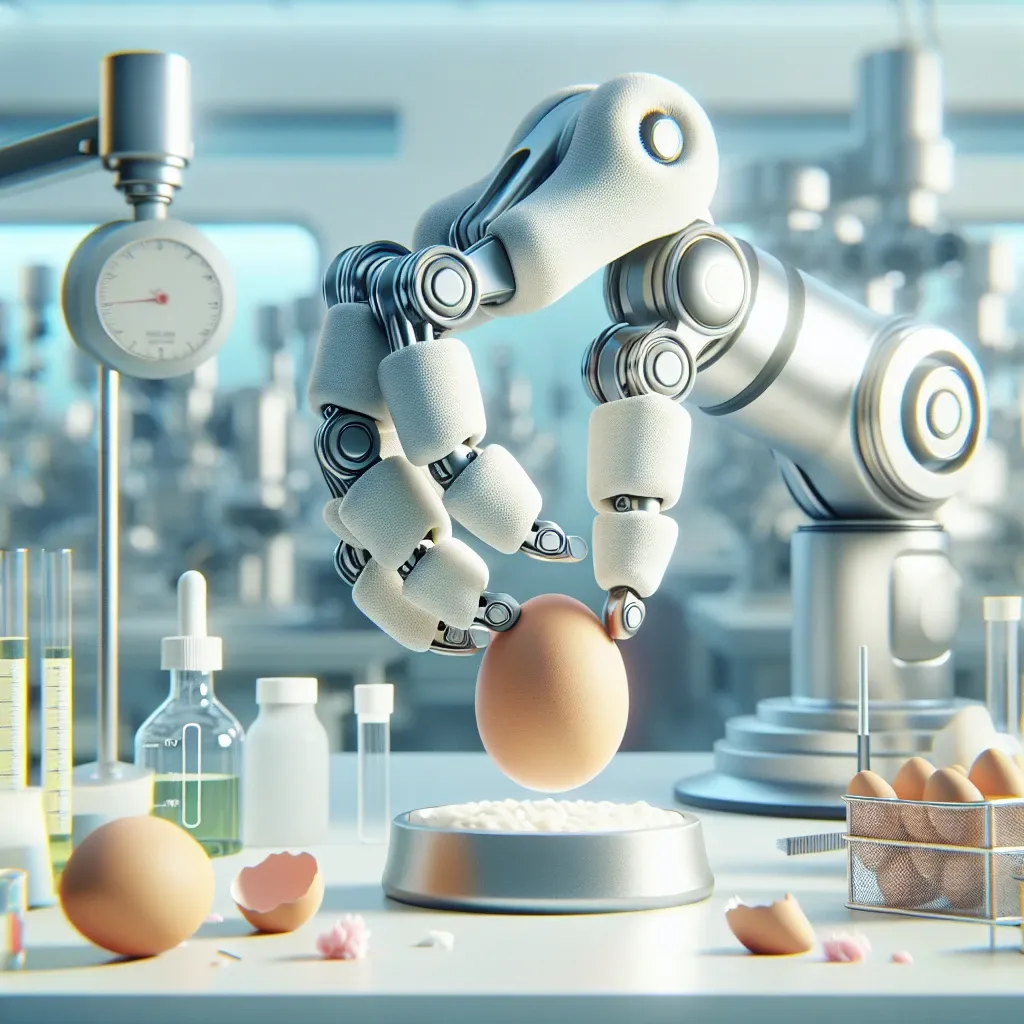

Introduction to Soft Robotics Grippers

In the field of robotics, the ability to handle delicate objects has long been a challenge. Traditional robotic grippers often use rigid materials that can be too harsh for fragile items. Enter soft robotics, a burgeoning field that seeks to replicate the flexibility and dexterity of the human hand. Soft robotics grippers are designed to handle delicate objects with an unprecedented level of human-like finesse, opening up a world of possibilities in various industries.

The Evolution of Robotics and the Rise of Soft Robotics

The concept of robotics dates back to ancient times, with automata appearing in historical texts and designs. However, it wasn’t until the late 20th century that robotics began to gain traction, thanks to advances in technology. Traditional robots were primarily constructed from rigid materials, limiting their utility in applications requiring dexterity.

Soft robotics began to emerge in the early 2000s, driven by the need for more adaptable and safer robotic systems. Researchers aimed to create robots that could mimic biological organisms, which often use soft, flexible bodies to navigate and interact with their environment. This led to the development of soft robotics grippers, which utilize compliant materials to achieve human-like dexterity.

What Are Soft Robotics Grippers?

Soft robotics grippers are robotic hands made from flexible materials such as silicone, rubber, or soft polymers. These components allow the grippers to conform to the objects they are handling, making them ideal for delicate, irregularly shaped, or fragile items. Unlike traditional grippers that may crush or damage sensitive materials, soft grippers can gently envelop and manipulate objects with precision.

Key Features of Soft Robotics Grippers

- Flexible Materials: Soft grippers are constructed from compliant materials that can deform without causing harm to delicate objects.

- Human-like Dexterity: They mimic the movement and grip of a human hand, allowing for intricate handling tasks.

- Versatile Applications: Capable of handling various types of objects, from fruits to electronics, soft robotics grippers are adaptable across multiple industries.

- Integration with Sensors: Many soft grippers are equipped with sensors to provide feedback on grip strength and object detection.

Applications in Various Industries

The versatility of soft robotics grippers has made them applicable in numerous industries:

1. Agriculture

In agriculture, soft grippers are used for harvesting delicate fruits and vegetables. Unlike traditional mechanical harvesters, which can bruise or damage produce, these grippers can gently pick fruits, ensuring minimal waste and maintaining quality.

2. Healthcare

In the healthcare sector, soft robotics grippers are employed in surgical applications where precision is paramount. They can manipulate tissues and organs gently during procedures, reducing the risk of damage and improving patient outcomes.

3. Manufacturing

In manufacturing, soft grippers can handle fragile components such as glass or ceramics, preventing breakage during assembly processes. Their ability to adapt to different shapes makes them ideal for collaborative robots working alongside human operators.

4. Logistics and Warehousing

Soft grippers are also being integrated into logistics and warehousing operations. They can sort and handle packages of varying sizes and materials, streamlining the shipping process while ensuring the integrity of the items being handled.

Benefits of Using Soft Robotics Grippers

The adoption of soft robotics grippers offers several advantages:

- Enhanced Safety: Their gentle handling reduces the risk of damage to fragile items, making them safer for both the objects and the operators.

- Increased Efficiency: Soft grippers can adapt to different tasks without the need for constant reconfiguration, improving operational efficiency.

- Cost-effective: By minimizing waste and damage, soft grippers can lead to cost savings in industries such as agriculture and manufacturing.

Challenges and Limitations

Despite their numerous advantages, soft robotics grippers are not without challenges:

- Durability: The materials used in soft grippers may wear out faster than traditional rigid components.

- Control Complexity: Achieving precise control over the grippers can be more complex due to their compliant nature.

- Cost of Development: Developing and integrating soft robotics technology can require significant investment.

Future of Soft Robotics Grippers

As technology continues to advance, the future of soft robotics grippers looks promising. With ongoing research focused on improving material durability and control algorithms, we can expect to see even more sophisticated solutions that can tackle a wider range of applications.

Moreover, the integration of artificial intelligence and machine learning will enable these grippers to learn from their environments and improve their performance over time. This will enhance their adaptability and efficiency, making them invaluable assets across industries.

Real-World Examples

Several companies and research institutions are pioneering the development of soft robotics grippers:

- Harvard’s Wyss Institute: Known for its groundbreaking work in soft robotics, the Wyss Institute has developed grippers that can pick and place delicate items with remarkable precision.

- Soft Robotics Inc.: This company specializes in soft automation and has created grippers designed for food handling and packaging, revolutionizing the way food products are processed.

Conclusion

Soft robotics grippers represent a significant advancement in robotic technology, allowing for the safe and efficient handling of delicate objects with human-like dexterity. Their applications span various industries, from agriculture to healthcare, demonstrating their versatility and potential to improve existing processes. Despite some challenges, the future of soft robotics grippers looks bright, with ongoing innovations poised to expand their capabilities further. As we continue to explore the possibilities of soft robotics, we can anticipate a transformative impact on how we interact with the physical world.